Lighthouses of England

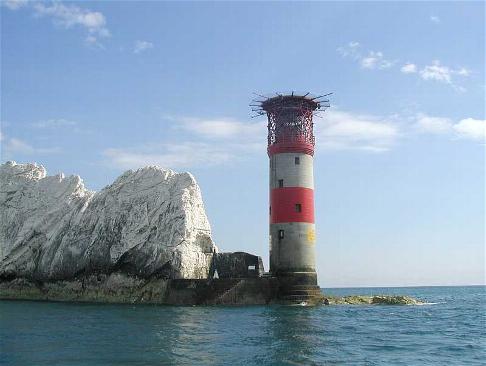

The Needles

The Needles, Isle of Wight (2002)

The magnificent chalk cliffs of Needles Point rise to a 450 ft (137 m) summit. In 1787 Richard Jupp supervised the construction of a squat 22 ft (6.7 m) high lighthouse on the top of the adjacent high cliffs, but within two years it had to be abandoned because it was enclosed in sea mist or fog for much of the time. On the 26th July 1857, construction of a new tower began on the end of Needles Point. The first course of stone was laid 3 ft (1 m) below the low water spring tide level. Each stone was dovetailed to the next one and anchored with gunmetal treenails. A further 3 courses of stones brought this base to a height of 21 ft (6 m). The remaining 39 courses of granite blocks raised the Needles tower a further 52 ft 5 ins (16 m) in height, to the underside of the cornice stones. At this level the structure is 20 ft (6.1 m) in diameter and the walls 2 ft 4 ins (0.7 m) thick.

The old lighthouse (above) was built on the hilltop where there is now a look-out post operated by Coastwatch volunteers.

The interior of the Needles lighthouse is divided into five apartments. The ground floor and main entrance was used as the oil room. Above the oil room was the provisions store. The next level contains the dining room, kitchen and living quarters. Purpose-built banana bunks and wardrobes were fitted in the bedroom area on the next level. The floor above is the watch room and provides access to the lantern room. When on duty the keepers spent the majority of their time in this area. Access to each level of the tower is by climbing an open plan geometrical steel staircase. The lantern is 23 ft 2 ins (7 m) in height and 13 ft 1 in (4 m) in diameter. On completion of this work, Chance Brothers of Birmingham installed their first order dioptric lens apparatus and the Fresnel multi-wicked oil burner. A clockwork mechanism was installed to turn the optic. This work involved the erection of a 1 ft (0.3 m) diameter hollow cast iron stanchion between the floor of the watchroom and lantern room. Its purpose was to support the weight of the dioptric apparatus and to contain the drive weight of the clockwork equipment that powered the 3 cwt (152 kg) fog bell. During foggy conditions this bell sounded continuously, but after 6 hours of operation, the heavy drive weight had to be rewound by hand to its starting position. When the Needles Point light was first lit on the 22nd May 1859, the total cost of the project was nearly £20,000. In May 1946 the existing oil room was converted to contain the diesel fuel for new generators.Along with the installation of the new catadioptric lens apparatus, a reed foghorn was fitted on the gallery with its electrically powered air compressor and air storage tanks sited in the lantern room. When this horn was in service it provided a 5 second blast every 20 seconds. The light source for the optics consisted of mercury vapour filament bulbs that provided an intensity of 1.5 kW. For emergency, these bulbs were sited on a 2-position lamp changer that contained three 36 watt standby lamps. A bank of batteries located in the service or watchroom provided the power for these standby lights. In case of mains failure, the emergency lights would remain operational for up to 72 hours. On the 8th July 1971 the existing reed horn was discontinued and replaced by two Supertyfon fog units. Their audible range was about 5 nautical miles. In service, the sequence of operation was a 1.5 second blast, 2 seconds silence, 1.5 second blast, followed by a 25 second period of silence, repeated every 30 seconds. In 1986, a helipad was fitted on top of the lantern. The landing platform was 26 ft 3 ins (8 m) in diameter, with a heavy duty tensile safety net 5 ft 6 ins (1.7 m) wide around its perimeter. By the 27th September 1987, the helipad was operational. Automation finally came just before Christmas, 1995. Today the Needles lighthouse is monitored from St. Catherine's lighthouse, further along the coast of the Isle of Wight.Magnificent chalk cliffs confront seafarers approaching the Solent from the west of the Isle of Wight. This part of the Isle of Wight is to the west of Freshwater Bay and gradually rises to a 450 ft (137 m) summit. From here is a view of a lonely lighthouse that stands at the extreme point of a line of chalk soldier rocks known as the Needles.In 1780 numerous shipowners and petitioned the Elders of Trinity House for a lighthouse near the Needles Rocks. Samuel Wyatt, the Corporation's Consultant Engineer and Architect advised the Elder Brethren to obtain the services of Richard Jupp. By 1787 Richard Jupp had supervised the construction of a squat 22 ft (6.7 m) high lighthouse and adjoining keepers quarters on the top of the high Needles Headland. But within two years the Corporation was forced to abandon the lighthouse because most of the time it was enclosed in sea mist or fog.In 1853 Trinity House instructed its consultant engineer, James Walker, to prepare the plans, specifications and estimates for erecting a lighthouse on the Needles Rocks. On the 26th July 1857, James Walker employed local stone masons and quarrymen, to begin the construction of the tower. The chalk surface of the Needles Point Rock was in conditions where the men were standing constantly in seawater. After 8 weeks of backbreaking work, the 3 ft (914 mm) thick granite foundation stones were set into position to form the 38 ft (11.58 m) diameter base for the tower. This first course of stone was laid 3 ft (914 mm) below the low water spring tide level. Above this, the base tapers in a stepped formation to 24 ft (7.32 m) in diameter and consists of 8 courses of chamfered granite blocks 2 ft (610 mm) thick. Each of these stones was dovetailed to the next one and anchored with gunmetal treenails. A further 3 courses of stones brought this base to a height of 21 ft (6.4 m).After the first course of the tower's walls was set into place, the upper 2 ft (610 mm) of its solid base was filled with concrete. This was surfaced with slate 1.5 ins (38 mm) thick with its top level set at 8 ins (203 mm) above the horizontal joint below the wall stones. This was to provide a barrier which would prevent the ingress of sea water through the walls and into the tower. At this level the tower is 21 ft (6.4 m) in diameter and the walls 3 ft 3 ins (994 mm) thick. The remaining 39 courses of granite blocks raise the Needles tower a further 52 ft 5 ins (15.99 m) in height, to the underside of the cornice stones. At this level the structure is 20 ft (6.1 m) in diameter and the walls 2 ft 4 ins (701 mm) thick. A solid moulded granite parapet wall 1 ft 3 ins (38l mm) thick and 3 ft 4 ins (1.02 m) high, tops the edge of the gallery stones.The interior of the Needles lighthouse is divided into five apartments. The ground floor and main entrance was used as the oil room. A curved tank capable of holding 2500 gallons (11,140 lts) of oil was constructed in this room. Above the oil room was the provisions store. The next level contains the dining room, kitchen and living quarters, which are comfortably fitted into an area 15 ft 6 ins (4.72 m) in diameter and 11 ft 3 in (3.43 m) high. Purpose-built banana bunks and wardrobes were fitted in the bedroom area on the next level. Each of these bunks had its own privacy curtain. The floor above is the watch room and provides access to the lantern room. When on duty the keepers spent the majority of their time in this area. Access to each level of the tower is by climbing an open plan geometrical steel staircase.A heavy stormproof entrance door constructed from gunmetal, was fitted on the ground floor. Each apartment has two gunmetal stormproof windows. From the rear of the tower to the sheer face of the Needles Rock, a 52 ft (15.85 m) long by 26 ft (7.92 m) wide landing stage was constructed out of coarsely dressed granite blocks and infilled by much of the excavated chalk and concrete. At this level the face of the Needles Rock was excavated to form two stores and an oil room. These rooms had heavy cast iron doors hung in their openings. Access to the tower from the landing stage was up a small semi-circular flight of granite steps. To allow the keepers to reach the top of the landing stage during low tide, two flights of step iron were fitted to the face of the granite blocks.While this work was in progress, the lantern was erected, a triangularly glazed unit 23 ft 2 ins (7.06 m) in height and 13 ft 1 in (4 m) in diameter. On completion of this work, Chance Brothers of Birmingham installed their first order dioptric lens apparatus and the Fresnel multi-wicked oil burner.

A clockwork mechanism was installed to turn the optic. This work involved the erection of a 1 ft (305 mm) diameter hollow cast iron stanchion between the floor of the watchroom and lantern room. Its purpose was to support the weight of the dioptric apparatus and to contain the drive weight of the clockwork equipment that powered the 3 cwt (152 kg) fog bell. During foggy conditions this bell sounded continuously, but after 6 hours of operation, the heavy drive weight had to be rewound by hand to its starting position.When the Needles Point light was first lit on the 22nd May 1859, the total cost of the project was nearly £20,000, but within a month Trinity House was receiving complaints that the light was not bright enough. At this time the maximum recorded range was 8-9 nautical miles on a clear night.

For nearly 35 years the only change to the operation of the Needles light was the installation of a Douglass constant level oil lamp. In 1906 the Corporation's Engineer-in-Chief, Sir Thomas Matthews, introduced an incandescent mantle burner. This type of lamp was adapted from the invention of Arthur Kitson and worked on the principle of paraffin gas. The oil was forced under pressure through a vaporiser and into a retort where it was heated. When a white fuming gas developed it was lit above the silk mantle. This lamp effectively trebled the output normally associated with wicked burners and reduced the oil consumption by nearly a third.The Second World War saw the Needles Point lighthouse being used on a regular basis for target practice by the gunners of German aircraft. This problem also occurred at the St. Catherine's lighthouse where, sadly, three keepers were killed during a bombing raid. At the Needles station the keepers used one of their storerooms, which had been carved out of the chalk rocks, as their air raid shelter. On several occasions the lighthouse was strafed by machine-gun fire, which shattered sections of the dioptric apparatus. Numerous panes of glass were broken and twice the station was bombed. Luckily the German bomb-aimers were not very good and all the bombs fell harmlessly into the sea. By the end of the War the lighthouse was in need of repair, although it is fair to say, that the keepers did a remarkable job in maintaining the light for the use of passing Allied shipping. It is also important to acknowledge that at no time was this station supplied with a means of defence.In May 1946 the existing oil room was converted to contain the diesel fuel for the generators. These were sited in the entrance room and consisted of 4 L2 Gardener alternator sets that produced 100 volts of electricity. Along with the installation of the new catadioptric lens apparatus, a reed foghorn was fitted with its electrically powered air compressor and air storage tanks sited in the lantern room. When this horn was in service it provided a 5 second blast every 20 seconds. Its horn was located on the Needles gallery, with the bell-mouth kept below the focal plane of the light. The light source for the optics consisted of mercury vapour filament bulbs that provided an intensity of 1.5 kW. In case of emergency, these bulbs were sited on a 2-position lamp changer that contained three 36 watt standby lamps. A bank of batteries located in the service or watchroom provided the power for these standby lights. In case of mains failure, or in the event that the keepers were unable to carry out a repair, the emergency lights would remain operational for up to 72 hours. Most of the modernisation programme at the Needles lighthouse was carried out by Chance Brothers and the electrical company of G.E.C. Ltd. This method of a 100 volt power supply would remain in operation for nearly 50 years.When the electrification programme was completed in October 1951, the recorded intensities for the Needles lighthouse were relatively the same. The white light had an intensity of 35,000 candle power with a visible range of 14 nautical miles. The red light was of the same value and visible distance, but the small sector beam over the Goose Rock had a new ruby screen fitted. The effect of this new screen gave the light an intensity of about 14,000 candle power and a visible distance of 9 nautical miles. Its green sector had an intensity of 8,000 candle power, with a visible range of nearly 7.5 nautical miles. After the project was analyzed following its completion, it was noted that very few problems had been encountered, but the cost of getting the materials and equipment to the Point was fairly high. The Elder Brethren of Trinity House therefore decided that further investigation into electrifying other rock-based lighthouses was needed.

On the 8th July 1971 the existing reed horn was discontinued and replaced by two Supertyfon fog units. Their audible range was about 5 nautical miles. In service, the sequence of operation was a 1.5 second blast, 2 seconds silence, 1.5 second blast, followed by a 25 second period of silence, repeated every 30 seconds.During April 1986, plans were drawn up for fitting a helipad on top of the lantern. This work involved the removal of the existing domed ventilator, with a new drum unit positioned in its place. Sections of the lantern roof were cut to form access trap doors and the iron handrail was taken away. All the materials and equipment for carrying out this work were transported to site by Bond Helicopters Ltd. The design of the helipad framework was similar to a helical lantern, which maximised the unobstructed light area without affecting the strength of its structure.The support framework of the helipad consisted of tubular steel stanchions that were erected and bolted into position around the lantern. Its square box-shaped steel framing came in three different sections, the lowest part formed into a 5 tier handrail style, the same height as the pedestal base of the lantern. Above this was erected the helically designed section, with its top portion of a similar arrangement as that at the bottom. Onto the stanchions and this steel supporting framework was laid the helipad itself. The overall height of this structure, from the gallery walkway to the top of the decking, was 21 ft (6.4 m). It was also 21 ft (6.4 m) in diameter. The landing platform was 26 ft 3 ins (8 m) in diameter, with a heavy duty tensile safety net 5 ft 6 ins (1.7 m) wide around its perimeter. At the four main points of the compass were positioned horizontal siting bars 6 ft (1.83 m) long, with yellow discs at their ends. Access panels were fitted into the helipad for entry into the lighthouse. Further hatches were formed for the water and diesel refuelling points. The maximum design weight for this helipad 3.5 ton (3.6 tonnes) By the 27th September 1987, the helipad was operational.Prior to the introduction of the Needles helipad, all relief changes and provision deliveries were normally carried out by a Trinity House tender or, on the rare occasion, by a helicopter using a hoist from the landing stage. But many of the relief trips were provided by a long-standing family of boatmen.

Automation finally came just before Christmas, 1995. Today the Needles lighthouse needs only the occasional inspection.